The Remarkable Efficiency of Pipe Repair Clamps

Author: Dewater Products Date Posted:5 September 2023

The Remarkable Efficiency of Pipe Repair Clamps

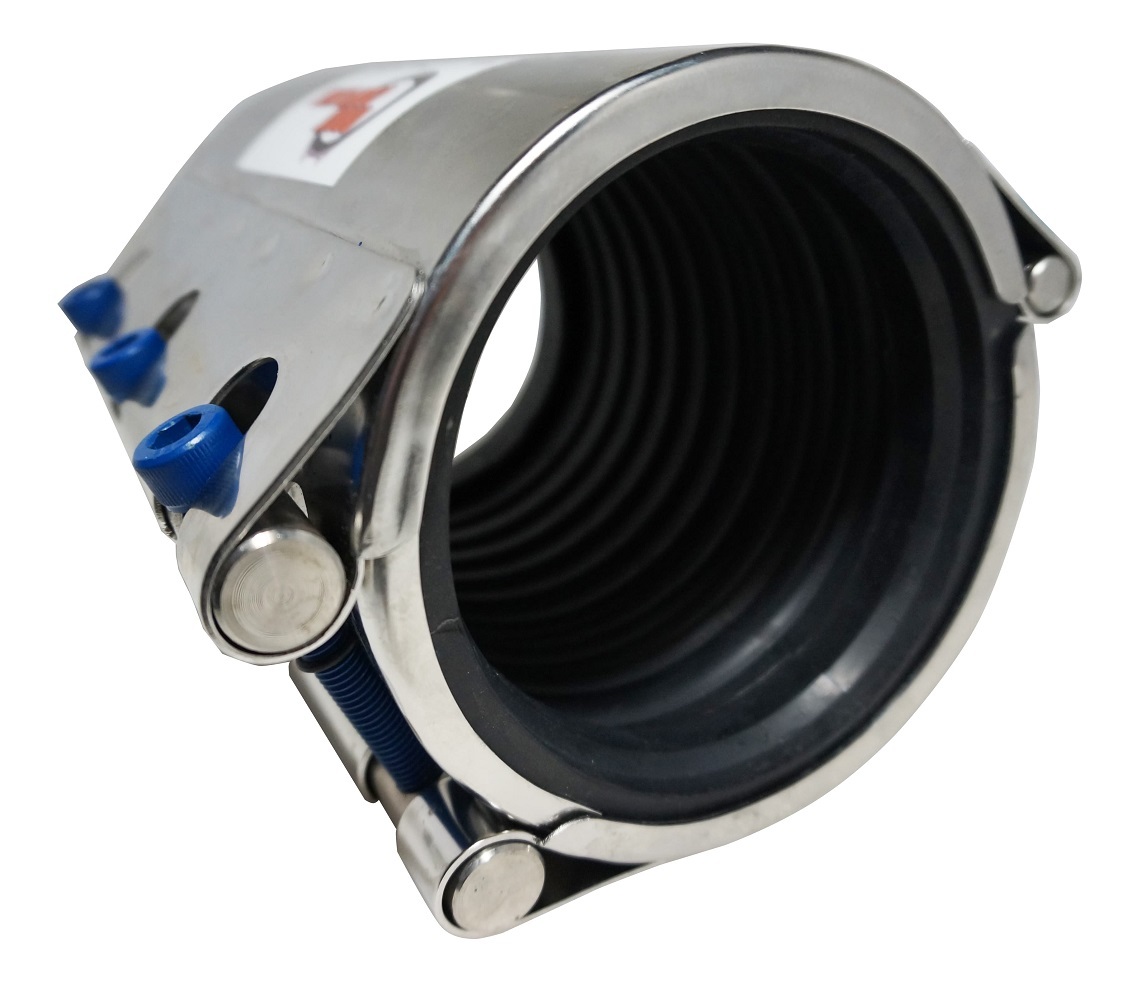

When it comes to repairing pipe leaks, there's a simple, cost-effective, and efficient solution that's often overlooked - the pipe repair clamp. Here's a deep dive into why these tools are indispensable for fixing piping leaks, and how to choose the right one for the job.

Why Use a Pipe Repair Clamp?

As pipes age, they're naturally prone to developing cracks and holes. This inevitably leads to leaks which can wreak havoc if not promptly addressed. However, before you jump into the thought of replacing an entire length of pipe, consider the alternative: a pipe repair clamp. Here's why:

Cost-Effective: Fitting a pipe repair clamp is generally more economical than replacing an entire length of pipe. Not only are the materials cheaper, but the labour costs and downtime are significantly reduced as well.

Minimal Disruption: Avoid the hassle and mess of excavation or construction work. Using a clamp ensures the repair is done above ground without the need for any heavy machinery or extensive manual labour.

Quick and Easy: A leak can be sealed in mere minutes with a pipe repair clamp. The process is as simple as wrapping the clamp around the affected area and tightening its bolts. Once tightened, the rubber sleeve inside the clamp creates a compressed seal around the leak, ensuring it's firmly closed off.

Choosing the Right Pipe Repair Clamp

When it comes to buying a pipe repair clamp, here's a quick guide to ensure you get the perfect fit:

Determine the Pipe's Outside Diameter size: The outside diameter, for instance, 219.1mm, will determine the size of the clamp. It's essential to measure this accurately.

Assess the Damage: Measure the diameter and length of the crack or hole. Ideally, the clamp you choose should have a length/width that's at least three times the size of the damage to ensure a secure fit.

Pick the Right Model: There's a wide array of clamps available, each designed for specific applications. Be sure to assess your needs and choose accordingly.

Specify the Pressure: Remember to provide the system's operating pressure when ordering, such as 1600kPa/16 Bar, to ensure your clamp can handle the pressure it will be subjected to.

Material Matters: Clamps made from 316 stainless steel are incredibly durable and perfect for long-term applications, especially for underground repairs.

Diverse Applications of Pipe Repair Clamps

Underground Water Pipes: These often suffer wear and tear due to their location. A durable clamp ensures a long-lasting repair.

Mining/Process Pipes: These are critical for operations and need speedy and efficient repair solutions.

Fluid Transfer Pipes: Any leak can lead to loss of valuable resources; clamps ensure quick fixes.

High-Pressure Water Mains: Here, the pressure specification is crucial. Ensure the clamp can handle the pressure to prevent further leaks.

Emergency Situations: For those unexpected pipe leaks, an emergency pipe repair clamp is a quick-fix solution.

Split Sleeve Repair: These specialized clamps offer an added layer of protection and sealing for larger damages.

The Science Behind Pipe Repair Clamps

While the concept of wrapping a clamp around a pipe might seem straightforward, the engineering behind it is far more nuanced. The design of the clamp, especially the rubber sleeve, often employs advanced materials science to ensure resilience, durability, and a perfect seal. The rubber, usually made of a material like EPDM or NBR, needs to be resistant to chemicals, temperature changes, and abrasion.

The Environmental and Safety Impacts

Water Conservation: With the current global emphasis on sustainability, a small leak, when multiplied across thousands of miles of piping in a city, can waste millions of gallons of water annually. Efficiently sealing leaks contributes to significant water conservation.

Safety: Gas and chemical leaks can be hazardous. By promptly sealing such leaks, pipe repair clamps play a pivotal role in averting potential disasters and ensuring the safety of workers and residents.

Environmental Protection: Leaks can contaminate groundwater and soil, affecting flora and fauna. Using clamps for immediate repairs helps in reducing the environmental footprint of industries.

Beyond Basic Repairs: Advanced Features of Modern Clamps

Anti-Corrosion Coatings: Many modern clamps come with coatings that resist rust and corrosion, prolonging the life of the repair and the clamp.

Modular Designs: Some clamps are modular, allowing for customized lengths to fit irregularly shaped or sized damages.

Temperature Flexibility: With pipes carrying superheated or supercooled liquids, clamps designed to withstand extreme temperatures are crucial.

Industries That Rely on Pipe Repair Clamps

Oil and Gas: Given the flammable nature of their contents, pipes in this industry need to be leak-free. Clamps offer quick solutions during unexpected leaks.

Agriculture: Irrigation systems rely heavily on pipes. Efficient water transport is essential for crop health, making clamps vital for quick repairs.

Municipal Services: From sewage systems to public water supply, city services require a network of pipes. Repair clamps ensure minimal disruption to public services.

Breweries and Distilleries: The art of brewing and distillation requires precision, and any leak can disrupt the process. Clamps help maintain the integrity of the production line.

Final Thoughts

Pipe repair clamps, while simple in operation, are a result of sophisticated engineering. They serve not just as quick-fix solutions but are essential for the safety, environmental conservation, and efficiency of various industries. As industries evolve and pipes carry more diverse contents under varying conditions, the technology behind these clamps will also need to innovate. However, their fundamental role in sealing, protecting, and ensuring continuity will remain invaluable.

Pipe repair clamps provide a quick, cost-effective, and efficient solution for addressing leaks in pipes. Whether it's an underground water pipe or a high-pressure water main, there's a clamp designed to address every need. So the next time you encounter a leak, remember, there's a clamp for that! If you have any questions about which pipe repair clamp is suitable for your application, please contact Dewater Products for advice.